The Power Of Hull MA: A Comprehensive Guide To Maritime Automation

The Power of Hull MA: A Comprehensive Guide to Maritime Automation

Related Articles: The Power of Hull MA: A Comprehensive Guide to Maritime Automation

Introduction

With great pleasure, we will explore the intriguing topic related to The Power of Hull MA: A Comprehensive Guide to Maritime Automation. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Power of Hull MA: A Comprehensive Guide to Maritime Automation

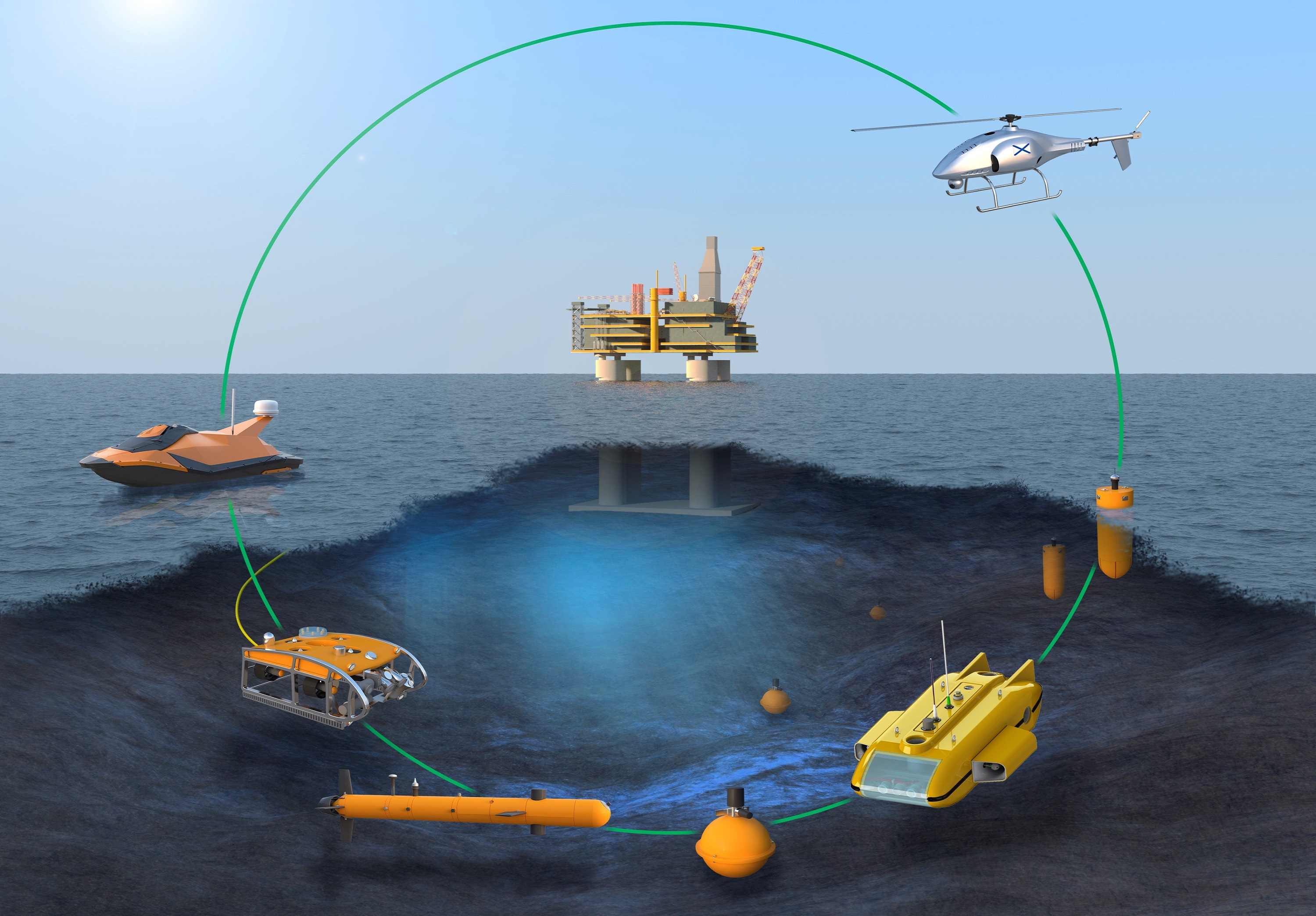

The maritime industry, a crucial artery of global trade, is undergoing a significant transformation fueled by technological advancements. One such innovation, Hull MA, stands as a pivotal force in this evolution, promising enhanced efficiency, safety, and sustainability. This guide delves into the intricacies of Hull MA, exploring its functionalities, benefits, and impact on the future of maritime operations.

What is Hull MA?

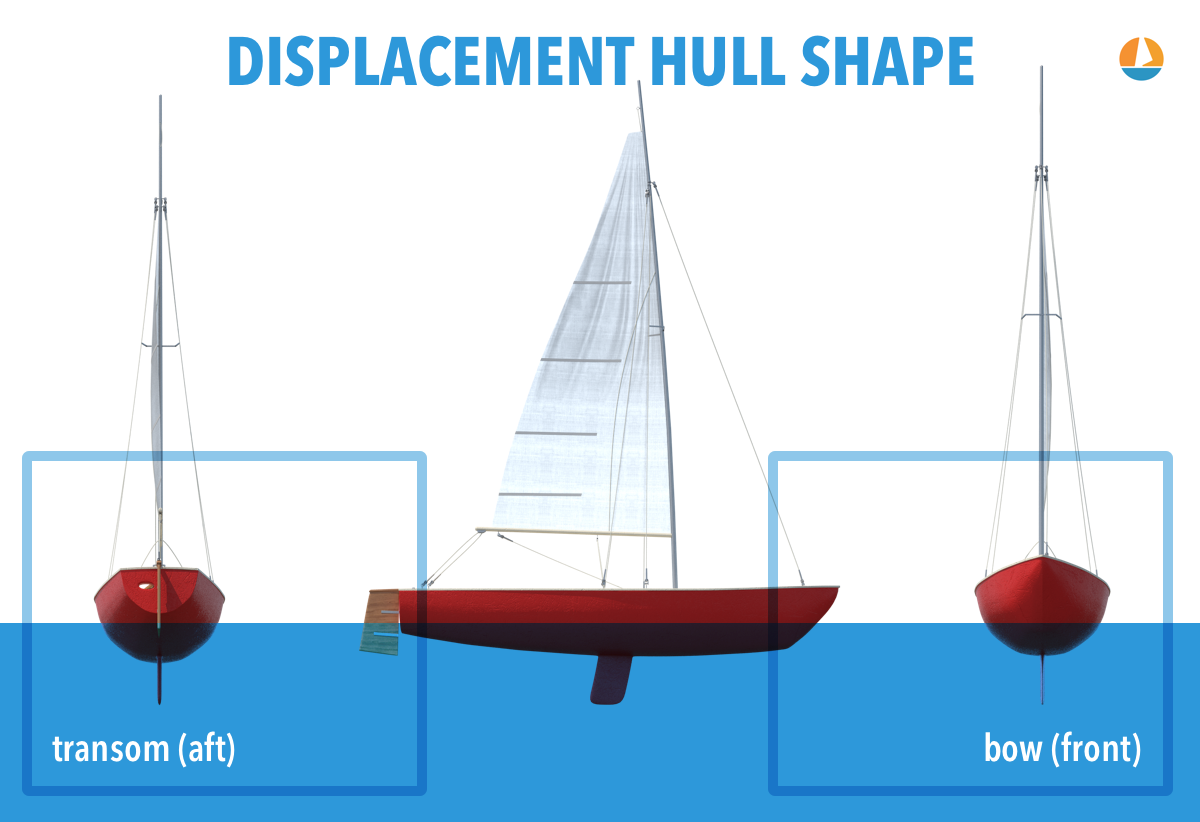

Hull MA, or Hull Management Automation, encompasses a suite of technologies designed to optimize the management and maintenance of vessel hulls. It leverages a combination of data analytics, predictive modeling, and automation to streamline processes, minimize downtime, and improve overall hull health.

Key Components of Hull MA:

-

Data Acquisition and Analysis: Hull MA systems collect vast amounts of data from various sources, including sensors, logs, and historical records. This data encompasses factors such as hull condition, environmental factors, and operational parameters. Advanced analytics tools then process this data to identify trends, anomalies, and potential issues.

-

Predictive Modeling: Based on the analyzed data, Hull MA systems generate predictive models that forecast potential problems with the hull, such as corrosion, fouling, or structural damage. These models provide early warning signals, enabling proactive maintenance and preventing costly and disruptive breakdowns.

-

Automated Maintenance Scheduling: Hull MA systems utilize the generated predictions to optimize maintenance schedules. They automate the process of scheduling hull inspections, cleaning, and repairs, ensuring timely interventions and maximizing operational efficiency.

-

Remote Monitoring and Management: Hull MA platforms enable remote monitoring of hull condition and performance. This allows operators to track key parameters, receive alerts on potential issues, and make informed decisions from anywhere in the world.

Benefits of Hull MA:

-

Enhanced Safety: By identifying potential hull issues early, Hull MA significantly reduces the risk of accidents and incidents, ensuring the safety of crew and cargo.

-

Increased Efficiency: Automated maintenance scheduling and proactive interventions minimize downtime, allowing vessels to operate at optimal performance levels.

-

Reduced Costs: Hull MA helps prevent costly repairs and delays by predicting and addressing issues before they escalate. It also optimizes resource allocation, minimizing unnecessary maintenance expenses.

-

Improved Sustainability: By reducing fuel consumption and emissions through optimized hull condition, Hull MA contributes to a more sustainable maritime industry.

Impact on the Maritime Industry:

Hull MA is poised to revolutionize the maritime industry by:

-

Transforming Maintenance Practices: Shifting from reactive to proactive maintenance strategies, minimizing downtime and improving operational efficiency.

-

Enhancing Vessel Performance: Optimizing hull condition and performance, leading to reduced fuel consumption and emissions.

-

Improving Safety and Risk Management: Proactively identifying and mitigating potential hull issues, enhancing safety and reducing the risk of accidents.

-

Driving Innovation: Creating new opportunities for technological advancements in the maritime sector.

FAQs on Hull MA:

Q: What types of vessels can benefit from Hull MA?

A: Hull MA is applicable to all types of vessels, including cargo ships, tankers, cruise liners, and even yachts.

Q: How does Hull MA address the challenges of corrosion and fouling?

A: Hull MA systems monitor hull condition for signs of corrosion and fouling, predicting potential issues and scheduling timely cleaning and maintenance to prevent further damage.

Q: What data sources are used by Hull MA systems?

A: Hull MA systems utilize data from various sources, including sensors, logs, historical records, environmental data, and operational parameters.

Q: How does Hull MA contribute to environmental sustainability?

A: By optimizing hull condition, Hull MA reduces fuel consumption and emissions, contributing to a more sustainable maritime industry.

Q: Is Hull MA a complex technology to implement?

A: While Hull MA involves advanced technology, reputable providers offer user-friendly platforms and support services to facilitate seamless implementation.

Tips for Implementing Hull MA:

-

Identify Clear Objectives: Define specific goals for implementing Hull MA, such as reducing maintenance costs, minimizing downtime, or improving safety.

-

Choose the Right Technology: Select a Hull MA system that aligns with the specific needs and requirements of your vessels and operations.

-

Ensure Data Integration: Ensure seamless integration of data from various sources to provide a comprehensive view of hull condition and performance.

-

Train Personnel: Provide adequate training for crew members and maintenance personnel on the operation and utilization of the Hull MA system.

-

Monitor and Evaluate: Regularly monitor the performance of the Hull MA system and evaluate its effectiveness in achieving the desired outcomes.

Conclusion:

Hull MA represents a transformative technology with the potential to revolutionize the maritime industry. By leveraging advanced data analytics, predictive modeling, and automation, it offers a powerful solution for optimizing hull management, enhancing safety, and driving efficiency. As the industry embraces this innovation, it will unlock new possibilities for a safer, more sustainable, and prosperous maritime future.

Closure

Thus, we hope this article has provided valuable insights into The Power of Hull MA: A Comprehensive Guide to Maritime Automation. We appreciate your attention to our article. See you in our next article!